*It is possible to control ± 5 ° C against melt temperature setting at 680°C.

*A bubbling device with H 2 gas of 0.2 to 0.3 cc can be provided in 100 g of molten metal (option).

*It is an energy-saving melting and holding furnace with a consumption unit of 500,000 Kcal / t.

*Combustion sound is quiet near the furnace body below 70 phones (dB (A)).

*There is no occurrence of hard spots due to the installation of filtration filter (option).

*Refractories The service life is extended to 4 to 5 years with special alumina refractories adopted

*(However, the useful life varies depending on the degree of care such as cleaning).

[ Features ]

· Energy Conservation

The gas immersion tube burner efficiently melts and holds with a small amount of gas (it is possible to recover waste heat inside the burner and recycle it into the furnace).

· Molten metal quality

By adopting immersion tube burner, molten metal temperature can be controlled uniformly to ± 3°C.

Also, due to immersion heating, the generation of oxide is reduced and the yield is improved.

· Environment

Effective insulation structure reduces surface radiant heat, improves ambient temperature environment, and realizes low noise (65 to 70 dB).

[ Description ]

It is a nonferrous metal molten metal holding furnace excellent in thermal efficiency and molten metal quality by inserting a ceramic permeable tube into the molten metal from the bottom of the side surface.

In addition to the conventional electric heater type, there is also a gas heating high efficiency heater.

[ Description ]

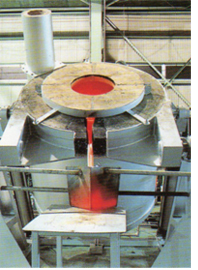

In aluminum molten metal holding, the holding furnace heats the melt surface directly from the ceiling surface of the holding chamber by flame.

Flat flame burner type, surface burning type such as metal knit burner, etc. are available.

[ Description ]

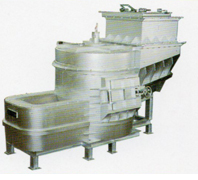

It is a thermally and structurally robust furnace body that has no blind spot and is easy to clean and fully exploits the characteristics of a large-scale concentrated melting furnace.

[ Description ]

The crucible type mel keeper is a compact dosing furnace that enables continuous melting using a graphite crucible.

It is an energy saving type docked tower part of a jet melter and a crucible furnace, high quality aluminum melt with few metal losses is obtained, features temperature control is easy and periodic furnace repair is unnecessary.

It is satisfactory for die casting, metal mold, sand mold casting.

* The generation of oxide was reduced by the luminous flame burner which was developed exclusively for aluminum melting.

* It is easy to clean, there is no blind spot, it is a thermally and structurally robust furnace body.

* We have eliminated the blockage of burner tiles.

* Energy saving, high yield (550,000 Kcal / t, 99 or more)

[ Description ]

Heat treatment of aluminum castings.

There is also a sand grinding combined furnace.

[ Description ]

It is a heat-efficient processing furnace that performs continuous heat treatment of aluminum casting (engine block and wheel).

[ Description ]

It is a package type system that incorporates an energy saving burner in the cover for ladle and can reliably recover waste heat.

The energy saving burner uses a STBW type in which a heat exchanger made of a heat resistant metal is provided inside, and the exhaust heat is recovered and the combustion air is preheated.